Ball bearings play a pivotal role in reducing friction between moving parts. Among these, deep groove ball bearings stand out for their versatility and efficiency.

This blog post delves into the nuances of shallow and Deep Groove Ball Bearings, their applications across various industries, and the key differences that set them apart.

Understanding Shallow and Deep Groove Ball Bearings

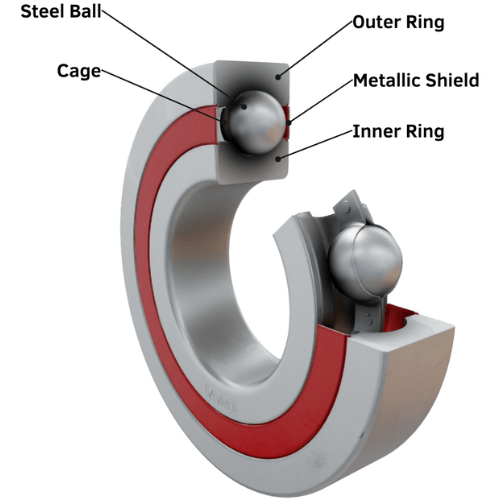

Ball bearings are designed to accommodate both radial and axial loads, making them essential in various mechanical applications. The primary difference between shallow and deep groove lies in the depth of their raceway grooves. Deep groove have deeper raceway grooves than their shallow counterparts, enhancing their radial load capacity.

Applications in Diverse Industries

Deep groove bearings, encompassing single and double-row variants, find extensive application across various sectors, from the automotive industry to aerospace technology. Their proficiency in managing high-speed operations and supporting radial and axial loads renders them perfectly suited for use in devices such as electric motors, gearboxes, and different types of pumps. Shallow groove bearings, while less common, are used in applications where space is limited and lower load capacities are sufficient.

While they may not be as widely recognized as their deep groove counterparts, their specific design and application cannot be understated. Shallow groove ball bearings, characterized by their less pronounced raceway grooves, cater to a niche yet significant range of mechanical needs.

Design and Characteristics of shallow groove bearings

The primary feature that distinguishes shallow groove bearings is the depth of their raceway grooves. Unlike deep groove bearings, which are designed to accommodate high radial loads, shallow groove bearings have shallower grooves, making them more suitable for applications where radial loads are moderate and space is a limiting factor. This design results in a smaller contact angle, which is ideal for applications requiring high precision but not necessarily high load capacity.

Applications and Suitability

Frequently found in small electric motors, domestic appliances, and various compact mechanical instruments, their construction facilitates a seamless and low-friction performance. This makes them a prime selection for scenarios, where reducing noise and maximizing space efficiency are paramount.

Advantages and Limitations

One of the main advantages of shallow groove bearings is their ability to operate quietly and efficiently in confined spaces. They are also typically easier to install and maintain due to their simpler design. However, their load-bearing capacity is limited compared to deep groove bearings. This makes them less suitable for heavy-duty industrial applications where higher radial and axial loads are prevalent.

Comparing Shallow and Deep Groove Bearings

The key differences between these two types of bearings include:

Load Capacity: Deep groove bearings can support higher radial loads due to their deeper raceways.

Design Variants: Deep groove bearings come in various designs, including those with seal or shield options and filling slots.

Speed Capability: High-speed applications often require deep groove bearings, thanks to their design efficiency and reduced frictional torque.

Deep Groove: Design and Efficiency

Deep groove bearings are designed to accommodate both radial and axial loads efficiently. Their design variants, including open bearings, sealed bearings, and those with filling slots, cater to a wide range of applications. The rolling bearing design minimizes frictional torque, making it suitable for high-speed operations.

Also Read: Mastering Bearing Tolerances

KG International’s Deep Groove Ball Bearings

At KG International, we specialize in providing high-quality deep groove bearings. Our bearings are designed to meet the diverse needs of various industries, offering optimal performance, durability, and reliability. Whether you need single or double row deep groove bearings, our products ensure reduced friction and enhanced load capacity.

Conclusion: Choosing the Right Bearing for Optimal Performance

Selecting the right type of bearing is crucial for ensuring optimal performance in mechanical applications. Deep groove bearings, with their high radial and axial load capacities and versatility, are often the preferred choice in many industries. At KG International, we understand the critical role these bearings play and are committed to providing top-tier solutions to meet your specific needs.