The worldwide bearings industry is crucial in numerous automotive, aerospace, and industrial machinery sectors. This blog analyses the bearings market, highlighting significant trends, obstacles, and prospects influencing the market landscape.

Essential to the machinery sector, bearings are pivotal for ensuring effortless rotation and reducing friction. As of 2022, the worldwide bearings market has reached a valuation of USD 117.8 Billion. This growth is driven by increasing demands in various significant sectors.

Market Dimensions and Classification:

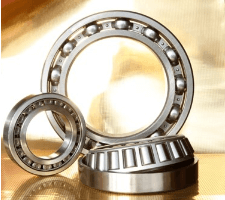

The bearings market is categorized into different types, such as ball bearings, roller bearings, and plain bearings, each serving distinct functions across various industries. The market-size differs regionally, with the UAE leading primarily because of its significant industrial growth and infrastructure advancements. This regional dominance is a result of the rapid industrialization and infrastructure development, making it a key player in the global bearings market.

The market segmentation into these specific types helps in segregating the needs of different industries, reflecting the diverse applications and requirements of bearings in various sectors.This segmentation and regional variation highlight the market complexity and the factors influencing its growth and development across the globe, which helps in finding the best bearing supplier near you.

Industry Evolution

The bearings sector is currently experiencing a significant boost in technological progress. Innovations in materials and design, along with meticulous engineering, are substantially improving the performance and durability of bearings. These advancements are technical and ecological as industry shifts towards sustainability. Bearing manufacturers are increasingly focusing on creating energy-efficient products, reflecting a commitment to environmental responsibility. This shift aligns with worldwide efforts to foster a more sustainable future, indicating a transformative phase in the bearings market where technology and eco-consciousness converge.

Sector-Specific Analysis

In the Automotive Industry: Bearings are integral to the automotive sector, especially with the growing popularity of electric vehicles. This surge in EVs fosters advancements in bearing technology to meet new demands.

Aerospace Industry Usage: In aerospace, bearings are essential for their reliability and ability to perform under harsh conditions. The aerospace industry consistently challenges the limits of bearing technology, seeking ever more robust and efficient solutions.

Role in Industrial Machinery: Bearings are critical components in industrial machinery, significantly boosting efficiency and minimizing operational interruptions. The global shift towards automation in various industries has increased the need for high-performance bearings. This trend reflects the evolution of business, adapting to technological advancements and changing market demands. As businesses innovate and automate, the bearing market is expected to grow, adapting to these new requirements and environments.

Market Dynamics

In the bearings industry, competition is fierce and KG International at the forefront. The major players are deeply invested in research and development, striving to stay ahead in the market. Their focus on innovation and technological advancements is a key aspect of their strategy to maintain market dominance. This competitive environment drives continuous product quality and performance improvements, benefiting various industries reliant on bearings. The commitment of these companies to R&D reflects their dedication to meeting evolving market demands and maintaining their positions as industry leaders. This competitive landscape ensures that the bearings market remains dynamic, with ongoing advancements and enhancements in product offerings.

Challenges and Opportunities in the Bearings Market

The bearings industry faces notable challenges and opportunities, particularly concerning raw material costs and global economic conditions. The price volatility of raw materials is a major challenge for manufacturers. Implementing strategic sourcing methods and fostering solid supplier relationships is essential to navigate this. These strategies help to stabilize costs and ensure a steady supply of materials.

On the other hand, global economic uncertainties present both challenges and opportunities. Economic fluctuations can affect the demand for bearings, potentially leading to reduced sales in specific markets. However, there’s a silver lining, as the continuous industrial growth in developing regions opens new avenues for market expansion. These emerging markets offer significant opportunities for growth, allowing companies to diversify their market presence and reduce dependency on more established economies. This dual aspect of challenges and opportunities underscores the dynamic nature of the bearings market, requiring adaptable and forward-thinking strategies from industry players.

Compliance Landscape

The bearings sector operates under stringent international trade rules and quality norms. Compliance with the industry standards is crucial for manufacturers to sustain their global market position.

Conclusion

The bearings industry is integral to contemporary industrial operations. Its substantial base, technological progress, and dedication to eco-friendliness set it up for a bright future. Successfully operating in this market demands a profound grasp of evolving trends, agile responses to obstacles, and a focus on providing top-notch solutions essential for the seamless functioning of industrial mechanisms. If you are finding a bearing supplier for your next project, KG International is your go-to supplier. From being a manufacturer of KG Bearings and distributor of renowned brands and it has built strong logistics around UAE. Contact us now to discuss your next big mechanical project.