In the intricate dance of manufacturing, every component and process play a crucial role in determining overall efficiency and productivity. One often-overlooked hero in this complex choreography is the industrial bearing. These unassuming yet indispensable components silently support machinery, reduce friction, and keep production lines moving smoothly. In this article, we explore how industrial bearings impact manufacturing efficiency and why selecting the right ones is paramount.

The Role of Bearings in Manufacturing

- Reducing Friction: Industrial bearings, including roller bearings and ball bearings, are designed to reduce friction between moving parts. In manufacturing, where machinery often operates at high speeds and under heavy loads, minimizing friction is key to efficiency. Bearings help machinery run smoothly, resulting in less wear and tear, lower energy consumption, and extended equipment life.

- Supporting Heavy Loads: Manufacturing machinery often handles substantial loads. Bearings distribute these loads evenly, preventing undue stress on individual components. This not only ensures the longevity of the machinery but also contributes to safer working conditions by reducing the risk of sudden failures.

- Maintaining Precision: Precision is vital in manufacturing, especially in industries like aerospace, automotive, and electronics. Industrial bearings are engineered to provide high levels of precision, ensuring that machinery operates with accuracy and consistency. This precision is essential for producing components that meet strict tolerances and quality standards.

Types of Industrial Bearings

Industrial bearings come in various types, each designed for specific applications

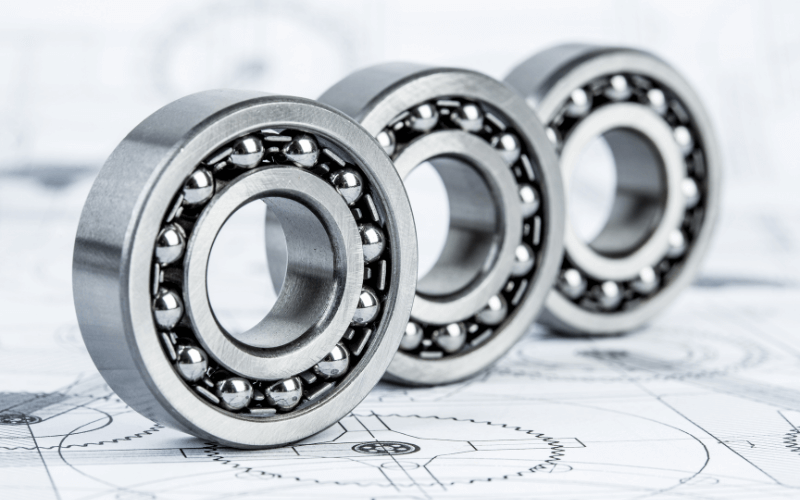

- Ball Bearings: Ball bearings are among the most common types of industrial bearings. They consist of steel balls placed between two rings (the inner and outer races). These bearings are highly efficient and suitable for both radial and axial loads. Ball bearings are commonly found in everything from conveyor systems to electric motors.

- Roller Bearings: Roller bearings, as the name suggests, use cylindrical or tapered rollers instead of balls. This design allows them to handle heavier loads and provide more surface contact. There are various types

The Impact on Manufacturing Efficiency

- Reduced Downtime: Industrial bearings, when properly selected and maintained, contribute to reduced downtime. Machinery that operates smoothly and experiences fewer failures due to wear and tear leads to uninterrupted production, higher output, and lower maintenance costs

- Energy Efficiency: Friction is a primary source of energy loss in manufacturing machinery. High-quality industrial bearings with low friction properties can significantly improve energy efficiency. Over time, this translates into substantial cost savings and a reduced carbon footprint

- Consistent Quality: In industries where precision is paramount, the consistent quality of industrial bearings ensures that each product meets exact specifications. This reduces waste and costly downtime

Choosing the Right Industrial Bearings

Selecting the right industrial bearings for your manufacturing operations requires careful consideration. Factors to keep in mind include:

- Load Requirements: Determine the types and magnitudes of loads your machinery will experience. Different bearings are designed to handle various load capacities.

- Speed: Consider the operational speed of your machinery. Some bearings are better suited for high-speed applications, while others excel in slower, heavy-load scenarios.

- Environmental Conditions: Bearings for harsh or corrosive environments may require special seals or materials.

- Maintenance: Follow the maintenance requirements of the bearings as specified by supplier.

Wrap Up

Industrial bearings are unsung heroes in the manufacturing world, quietly contributing to increased efficiency, reduced downtime, and improved product quality. Selecting the right bearings for your machinery is a strategic decision that can impact the bottom line and your overall competitiveness.

At KG International, we understand the significance of reliable industrial bearings in manufacturing operations. Our extensive range of high-quality bearings caters to diverse industrial needs. Whether you need ball bearings, roller bearings, or specialized bearings for unique applications, we have you covered. Make the smart choice for your manufacturing efficiency—choose KG International for your aftermarket parts requirements.

Remember, in the world of manufacturing, every component matters, and the right industrial bearings can make all the difference in optimizing your processes and achieving superior results.