Construction and mining tools include excavators, loaders, bulldozers, and dump trucks. They do things like move stuff, dig, build roads, and unload. These machines are essential for building and mining work. They often have to work on rough ground when they’re being used. Parts of these machines, especially the bearings, must handle things like dirt, heavy loads, bumps, shakes, and speed changes. The mining and construction industry uses various equipment and machinery, including excavators, loaders, backhoes, bulldozers, dump trucks, graders, cranes, forklifts, and off-road dumpers.

Key Features of Bearings Used in the Heavy Machinery Industry

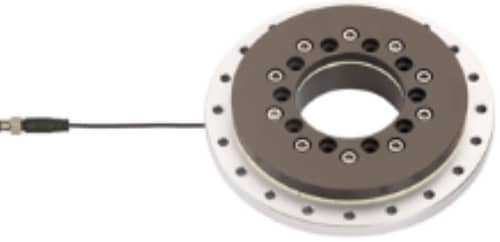

Bearings are integral components in many machines, and their features directly impact their performance and longevity. Here, we’ll take a closer look at some of the standout features of bearings:

Ready-to-Assemble: Bearings are pre-set, meaning they can be assembled right out of the box. This ensures that each bearing has precise measurements and gaps, smoothing the assembly process.

Built for Heavy Duty: These bearings are not just regular bearings. They are specifically designed to carry heavy loads. This design focus not only enhances their functionality but also increases their durability, ensuring they last longer even under strenuous conditions.

Resilience is Key: Have you ever had a situation where things didn’t align perfectly? These improved bearings have got you covered. They perform impressively even when faced with sudden impacts or when they aren’t perfectly aligned. This is a testament to their robust design and resilience.

Protection Against Contaminants: One of the prime concerns with bearings is the potential damage from dirt and contaminants. But with special seals in place, these bearings are well protected against a moderate to high level of such threats, ensuring a longer and more efficient lifespan.

Optimized Interior Design: It’s not just about the exterior; what’s inside counts, too. The interior of these bearings has been meticulously optimized. Coupled with a specially designed roller, these bearings can adjust to misalignments during use, making them adaptable and efficient.

Bearings are the Backbone of Heavy Equipment Industry

Picture a bustling construction site. It’s filled with towering cranes, robust excavators, and hardworking bulldozers. Can you even envision such a place without these colossal machines? It’s challenging! These behemoths make tasks that would be otherwise daunting or even impossible for human hands look easy.

The unsung heroes are the bearings – small yet mighty mechanical wonders tucked away inside these machines. Bearings act as the mediators that allow two moving parts to glide smoothly over each other. They minimize the resistance or friction that might slow the motion, ensuring energy is used efficiently. These bearings are indispensable in ensuring everything runs smoothly, especially in heavy-duty equipment, where the stresses are massive, and the working conditions can be challenging.

Strategies For Ensuring Bearing Reliability

Selecting the Right Bearings: The choice of bearing type is crucial. Engineers must select bearings that match the specific requirements of the machinery and its operational environment. This includes considerations of load capacity, rotational speed, and resistance to environmental factors.

Material Matters: Bearings are available in various materials, including steel, ceramics, and polymers. High-quality steel bearings with superior load-bearing capacity are often preferred for heavy machinery.

Sealing and Protection: Robust sealing mechanisms keep out contaminants and moisture. Innovative designs and materials for seals and shields contribute to extended bearing life.

Advanced Lubrication: Optimal lubrication significantly impacts bearing longevity. Heavy machinery demands specialized lubricants to withstand extreme conditions and maintain a stable film between moving surfaces.

Condition Monitoring: Implementing condition monitoring systems can detect early signs of bearing wear or damage, allowing for timely maintenance and replacements. This minimizes unexpected downtime.

Regular Maintenance: Scheduled maintenance routines that include inspection, lubrication, and potential replacement of worn bearings are essential for prolonging machinery life.

What are the trendiest bearing types?

Smart Bearings: Imagine bearings that talk back! Well, not literally, but close. These bearings come with embedded sensors that indicate the current condition.

Smart Bearings: Imagine bearings that talk back! Well, not literally, but close. These bearings come with embedded sensors that indicate the current condition.

Self-Lubricating Bearings: Let’s be honest, manual lubrication can be a messy affair. Self-lubricating bearings have built-in lube systems, slashing the need for manual greasing and making maintenance a breeze.

Self-Lubricating Bearings: Let’s be honest, manual lubrication can be a messy affair. Self-lubricating bearings have built-in lube systems, slashing the need for manual greasing and making maintenance a breeze.

High-Temperature Bearings: Have you ever wished bearings could handle the heat better? Thanks to material advancements, these new bearings can sizzle without fizzling out, widening the array of applications they’re suitable for.

High-Temperature Bearings: Have you ever wished bearings could handle the heat better? Thanks to material advancements, these new bearings can sizzle without fizzling out, widening the array of applications they’re suitable for.

Corrosion-Resistant Bearings: For all those industries where conditions can get a bit rough and aggressive, these bearings are the knights in shining armor. Crafted with special coatings and materials, they stand tall, resisting corrosion like a pro.

Also Read Types of Bearing, Applications Functions in the Industry.

Partner with KG Bearings

Behind every massive crane and powerful bulldozer, there’s an unsung hero: KG Bearings. They’re the quiet champions ensuring that these giants operate smoothly, safely, and efficiently. As technology advances, reshaping the world of heavy machinery, KG Bearings doesn’t just keep pace; we keep setting new standards for reliability.

Contact Kg International for more details!