In various industries, the need for reliable, high-performance components is essential for the efficient operation of machinery. Among these components, angular contact ball bearings play a critical role, especially in applications where both axial and radial loads are present. These bearings are designed to improve load-bearing capacity and boost operational efficiency, making them indispensable in fields such as automotive, aerospace, and manufacturing.

In this article, we will explore how angular contact ball bearings enhance load-bearing capacity and efficiency, their unique features, and the benefits they bring to different industrial applications.

Understanding Angular Contact Ball Bearings

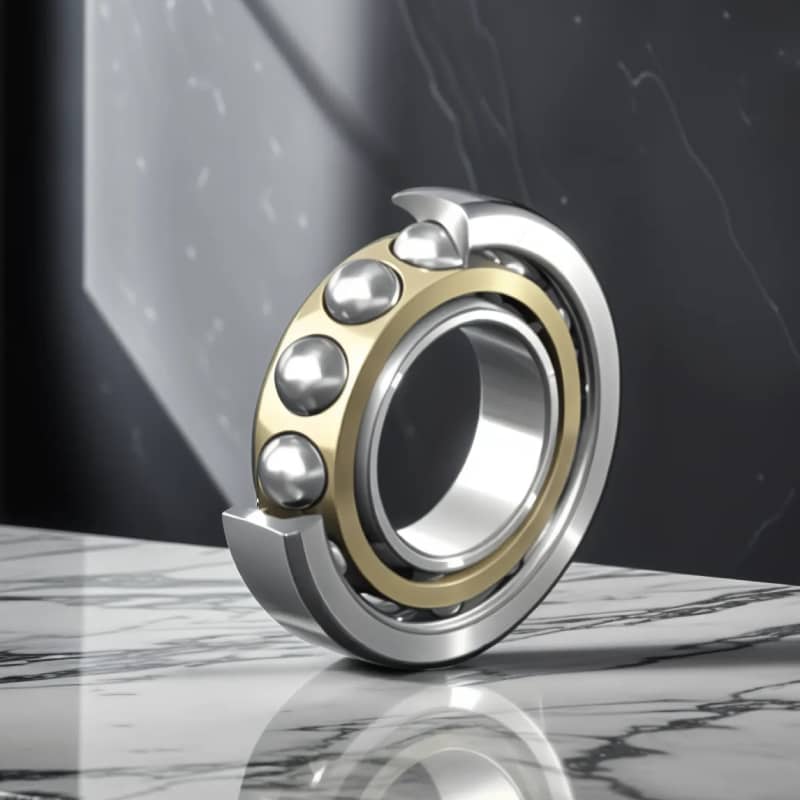

Angular contact ball bearings are specifically designed to handle both axial and radial loads simultaneously. Unlike standard ball bearings, where the load is applied perpendicular to the axis of the bearings, angular contact ball bearings have an inner and outer raceway that is slightly offset from each other. This angular displacement enables the bearings to accommodate higher axial loads in one direction, as well as moderate radial loads.

Key Features of Angular Contact Ball Bearings

To understand how angular contact ball bearings improve performance, it’s important to look at some of their key features:

- Axial and Radial Load Support: Angular contact ball bearings are unique in their ability to support both axial (thrust) and radial loads, which is essential for high-speed applications.

- Precision and Rigidity: These bearings are manufactured with high precision, ensuring minimal friction and maintaining rigidity under load, which is crucial in high-performance applications.

- High-Speed Operation: Their design supports high rotational speeds, which is why they are commonly found in machinery that requires both speed and load-handling capabilities.

- Durability: Built for long-lasting use, angular contact ball bearings are often made from high-quality materials that withstand wear and tear, even in demanding conditions.

How Do Angular Contact Ball Bearings Improve Load-Bearing Capacity?

The load-bearing capacity of angular contact ball bearings comes from their unique geometry. Because the raceways of these bearings are angled, they can accommodate axial loads more effectively than standard ball bearings. In a typical angular contact bearing, the load is transferred through the balls at an angle, allowing the bearings to handle both radial and axial forces in one direction.

This configuration is particularly useful in machines that experience a combination of forces. For instance, in automotive engines or industrial machinery, angular contact ball bearings help manage the multiple forces that occur during operation, allowing the equipment to function more smoothly and with less wear.

By distributing loads more evenly, angular contact ball bearings reduce stress on the bearing, increasing its overall lifespan and allowing it to support heavier loads without sacrificing performance.

The Role of Angular Contact Ball Bearings in Efficiency

Efficiency is key in modern machinery, where reducing energy consumption and friction is essential for optimal performance. Angular contact ball bearings contribute to efficiency in several ways:

- Reduced Friction: The precision design of angular contact ball bearings minimizes friction between moving parts. Less friction means less heat generation, which leads to improved energy efficiency and reduced wear on the bearings alone.

- Improved Load Distribution: The ability to handle both axial and radial loads helps angular contact ball bearings distribute forces more effectively. This reduces the strain on other components in the system, enhancing the overall efficiency of the machine.

- High-Speed Capabilities: Many industries, especially those involving high-speed machinery, benefit from the speed-handling capabilities of angular contact ball bearings. Their ability to maintain efficiency at high rotational speeds makes them a preferred choice for improving the performance of motors, turbines, and other high-speed applications.

Types of Angular Contact Ball Bearings and Their Applications

There are several types of angular contact ball bearings, each designed for specific industrial applications:

Single-Row Angular Contact Ball Bearings: These are designed to handle axial loads in one direction. They are typically used in high-speed applications like pumps, compressors, and gearboxes.

Double-Row Angular Contact Ball Bearings: These bearings can handle axial loads in both directions and are more compact. They are ideal for applications requiring high rigidity, such as machine tools and wind turbines.

Four-Point Angular Contact Ball Bearings: A unique type of angular contact bearings that can support axial loads in both directions with minimal radial load capacity. They are often used in applications where space is limited, but load-handling is critical.

These variations allow angular contact ball bearings to be used in a wide range of industries, from automotive to aerospace, and manufacturing to robotics.

Maintenance Tips to Extend the Life of Angular Contact Ball Bearings

To ensure that angular contact ball bearings operate efficiently and maintain their load-bearing capacity, proper maintenance is essential. Here are some best practices:

- Regular Lubrication: Keeping the bearings well-lubricated reduces friction and wear. It’s important to use the appropriate type of lubricant for the bearing’s operating conditions.

- Alignment Checks: Misaligned bearings can lead to uneven load distribution, which can shorten their lifespan. Regular alignment checks can prevent premature failure.

- Routine Inspections: Regular inspections help identify any signs of wear, corrosion, or damage before they cause serious problems. This can extend the life of the bearings and improve overall efficiency.

- Temperature Monitoring: Excessive heat can damage bearings. Monitoring the temperature during operation can help detect potential issues early on.

Conclusion

Angular contact ball bearings are a key component in improving both load-bearing capacity and efficiency in a wide range of industries. Their unique ability to handle axial and radial loads, coupled with high-speed performance and durability, makes them an invaluable asset in high-performance machinery. By reducing friction, improving load distribution, and supporting efficient operation, angular contact ball bearings ensure that machinery operates smoothly and effectively, even under demanding conditions.

When it comes to sourcing high-quality angular contact ball bearings, KG International stands out as the leading distributor. With decades of experience in the bearings industry, they deliver reliable, durable, and precision-engineered solutions tailored to your specific business requirements. Their extensive product range, coupled with exceptional customer experience and global reach, ensures that your business always has access to the best products, on time and at competitive prices.

Whether you operate in automotive or manufacturing, trust KG International to provide the bearings that enhance performance, efficiency, and longevity in your machinery. Contact KG International now to support your business with world-class bearing solutions.