In the competitive and increasingly regulated field of commercial transportation, operational efficiency and environmental impact of any vehicle are of utmost importance. European truck filters, designed to meet rigorous standards, are vital in optimizing these aspects by improving fuel efficiency and reducing harmful emissions. This blog aims to provide information about the mechanics and benefits of these filters, providing insights into their critical role in the transportation industry.

Understanding European Truck Filters

European truck filters are essential for maintaining the cleanliness and efficiency of the fuel system in commercial vehicles. Specifically engineered to adhere to stringent European standards, these filters ensure that trucks perform better and have a significantly reduced environmental footprint. By capturing dirt, rust, and other particulates before they can reach the engine, these filters maintain an optimal environment for combustion. This enhances the performance of the engine and extends its operational life, contributing to overall vehicle efficiency and reliability.

How Truck Filters Enhance Fuel Efficiency and Reduce Emissions

The crucial role of European truck fuel filters is to purify the fuel by removing various impurities that could potentially damage the engine. Cleaner fuel translates directly to more efficient burning, enhancing fuel economy. Moreover, by preventing these contaminants from reaching and potentially clogging the fuel injectors, these filters ensure a consistent and fine fuel spray, promoting complete and efficient combustion. The result is a substantial reduction in the volume of unburnt fuel and, consequently, a significant decrease in emission levels. This helps truck fleets meet strict environmental regulations and contributes to cleaner air.

The Role and Function of European Truck Filters

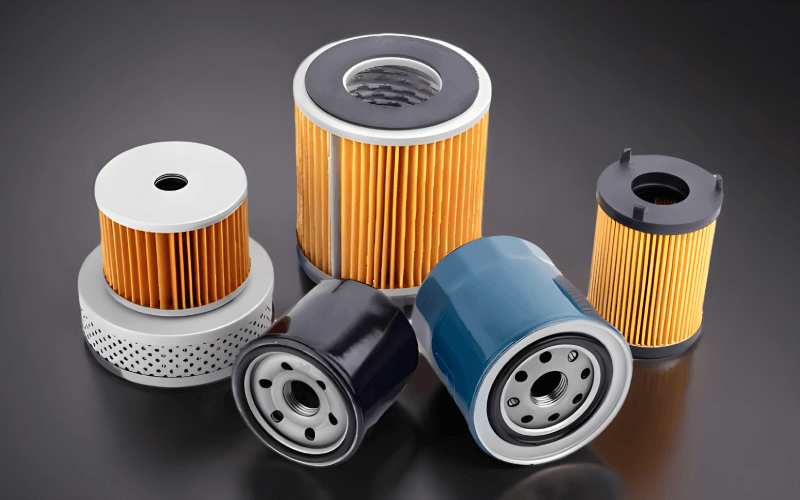

These filters encompass a variety of types, each serving a distinct and vital purpose:

Fuel Filters: These filters are crucial for cleaning the fuel of impurities, ensuring that only clean, efficient fuel reaches the engine.

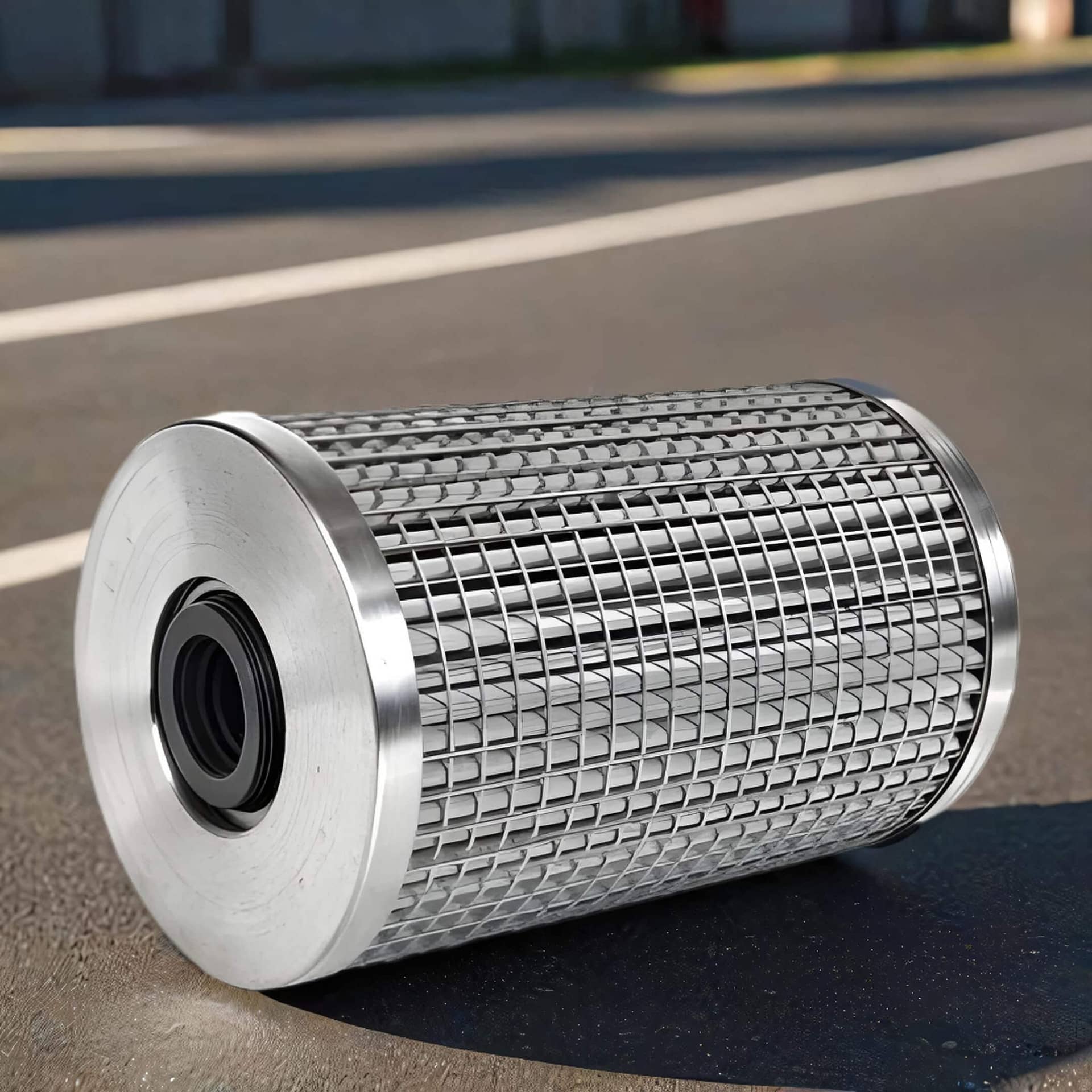

Oil Filters: Important for removing contaminants from engine oil, these filters protect engine components, reduce wear and tear, and extend the lifespan of the engine.

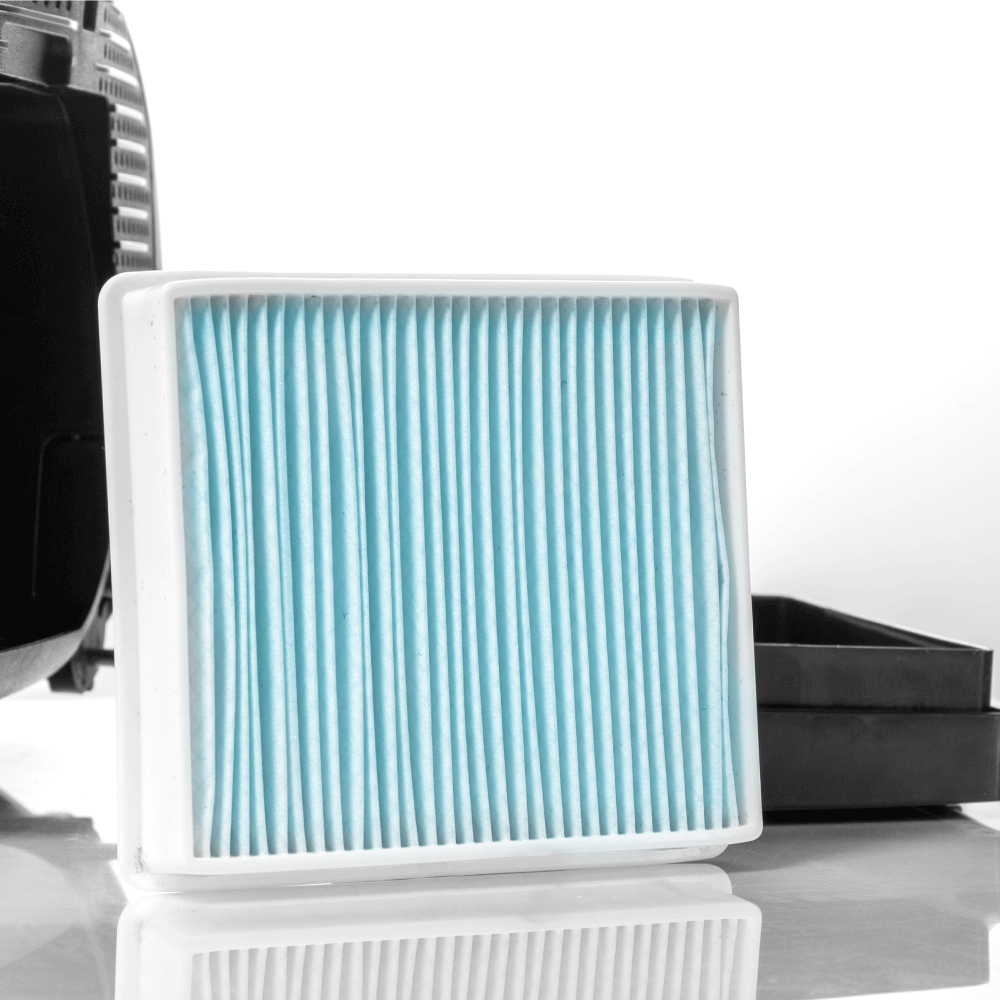

Air Filters: They block harmful particulate matter and debris from entering the engine, guaranteeing that only clean air combines with the fuel for optimal combustion.

Key Considerations When Choosing Truck Filters

Selecting the appropriate European truck filter requires evaluating several crucial factors to guarantee optimal performance and compatibility:

- Compatibility: It is essential to ensure that the filter is specifically designed to fit the model and make of the truck to avoid any mismatches that could affect performance.

- Micron Rating: This indicates the size of particles the filter can capture. A lower micron rating corresponds to finer filtration, which protects sensitive engine components.

- Flow Rate: The selected filter must support the flow rate required by the engine to prevent any possibility of fuel starvation, which can lead to engine inefficiencies or failures.

- Quality: Opting for filters made from high-quality materials ensures not only the efficiency of filtration but also the durability and longevity of the filter.

The Significance of Clean Fuel

The critical role of clean fuel in ensuring the operational efficiency of trucks is immense and cannot be overstated. When fuel is clean, it burns more completely, which allows the engine to operate at its best. This ensures smooth running, optimizes fuel consumption, and significantly minimizes the emission of harmful pollutants into the environment. Conversely, contaminated fuel can cause many engine issues—from clogged fuel injectors to premature wear and tear of engine components. Such problems lead to increased maintenance costs and a noticeable reduction in the overall reliability and lifespan of the vehicle. Thus, investing in high-quality truck filters is essential for maintaining fuel purity. This enhances the performance and safeguards the vehicle against potential costly repairs, ensuring operational efficiency and reliability.

KG International: Pioneering in Fuel Filtration Excellence

At KG International, we recognize the crucial role that fuel filtration plays in maintaining the efficiency and longevity of European trucks. Our selection of truck filters is designed to adhere to the highest performance and quality standards. By selecting filters from KG International, fleet managers ensure their vehicles operate at their best and benefit from reduced maintenance downtime and lower operational costs.

Conclusion

The role of European truck filters in modern commercial transport is critical for enhancing fuel efficiency and reducing emissions. KG International is at the forefront of providing superior fuel filtration solutions. Our commitment to quality and thorough knowledge of the European truck market positions us as a preferred partner in the automotive industry. For more information on our products and how KG can help maintain your fleet, visit our website at www.kginternational.com.

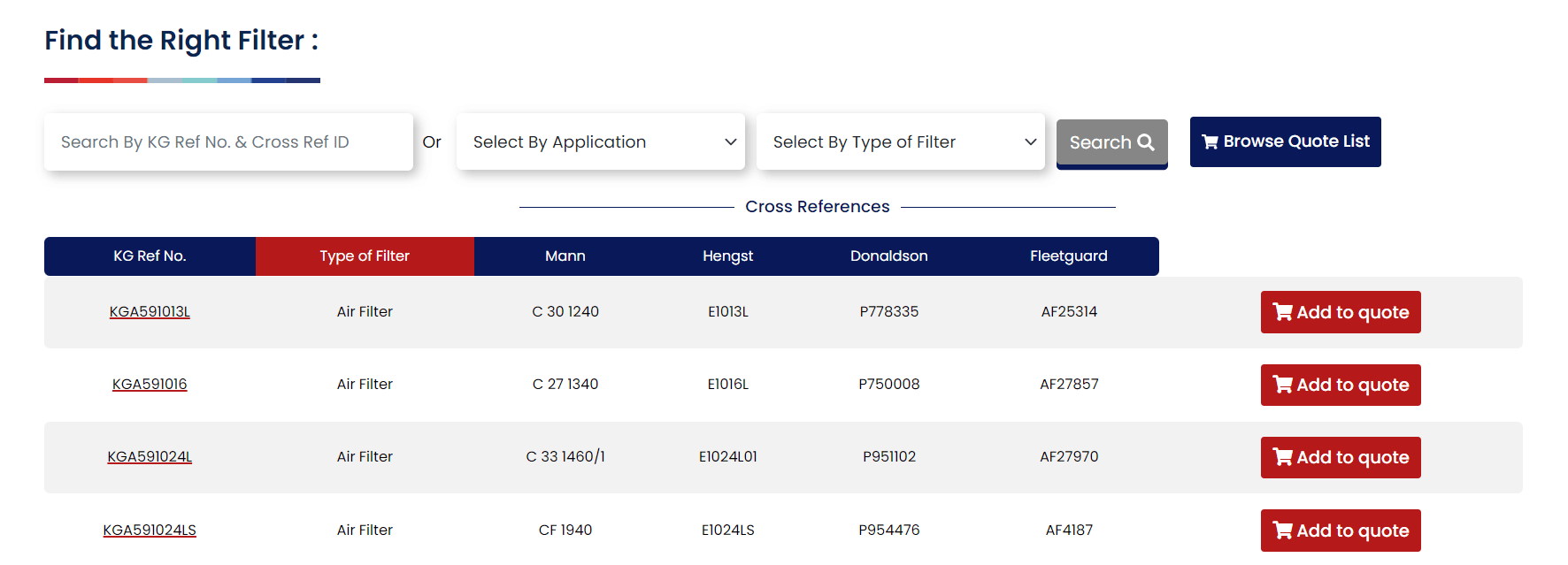

Also, you can browse through the variety of filters using E-catalog which has been specifically designed to ease your search for a suitable filter to fulfill your requirements. To find your way to KG Filter’s E-catalog, you can simply go to the KG International website by typing the domain address as www.kginternational.com. On the homepage of the website, please lick on the E-catalog button on the top right corner:

On the following page, click on KG Filters box:

It will lead to the below screen where you can either scroll through the list of filters or may also customize your search adding the text in the given boxes:

European truck filters are more than just components, they are essential investments that enable compliance with environmental standards, enhance vehicle efficiency, and contribute to operational cost savings. KG International remains dedicated to leading the way in fuel filtration technology, ensuring our clients receive the best performance and value.