When it comes to bearings, the world of industrial machinery relies on a variety of types to ensure smooth and efficient operation. One such category that stands out for its versatility and ability to handle diverse loads is Angular Contact Ball Bearings. In this comprehensive guide, we’ll delve into the design, features, and classifications of Angular Contact Bearings, shedding light on their crucial role in various applications

The Anatomy of Angular Contact Ball Bearings

Angular Contact Ball Bearings are engineered with a specific purpose in mind: to maintain a precise contact angle between the raceways and the ball, primarily in the radial plane. This fundamental design feature enables them to excel in applications where combined radial and axial loads are present. Let’s take a closer look at their key characteristics.

Contact Angle and Raceways

The distinctive feature of Angular Contact Bearings is the carefully designed contact angle between the balls and the raceways. This angled arrangement allows these bearings to sustain both radial and axial loads effectively. It’s this contact angle that sets them apart from Deep Groove Ball Bearings.

Cage Materials and Rolling Elements

Angular Contact Bearings typically employ cage materials made of pressed steel, high-strength brass, or synthetic resin. These cage materials are chosen for their durability and ability to withstand the demands of various applications. As compared to Deep Groove Ball Bearings, Angular Contact Bearings generally carry a higher number of rolling elements (balls). This increased number of rolling elements contributes to their enhanced load-bearing capacity.

Classification of Angular Contact Ball Bearings

Angular Contact Ball Bearings are further classified into three sub-categories, each tailored to specific needs and applications:

- Single Row Angular Contact Bearings

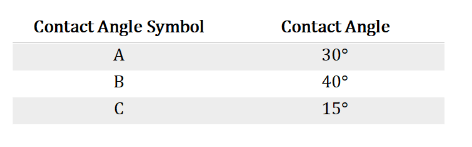

Single-row angular Contact Bearings come in three different contact angle classifications, allowing them to adapt to varying load requirements.

- Double Row Angular Contact Bearings

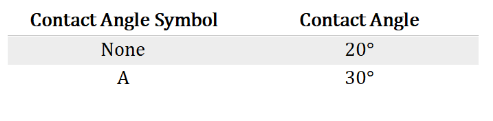

Double Row Angular Contact Bearings feature two different contact angle classifications, providing versatility in load-bearing capabilities.

- Combination Type Angular Contact Bearings

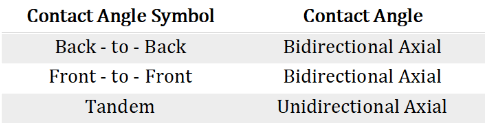

Combination Type Angular Contact Bearings are typically used in combinations of two or more units, offering a range of load-handling possibilities. Three different combinations are available to suit diverse industrial needs.

Key Advantages

Angular Contact Ball Bearings are known for their potential to carry both axial and radial loads, making them suitable for low, medium, and high-speed applications. KG International, a globally renowned bearing supplier, offers an array of Angular Contact Bearings tailored to your specific needs:

- Open basic design types for both Single and Double Row Angular Contact Ball Bearings.

- Sealed types for enhanced protection.

- Variants with Snap Ring grooves and Snap Rings for added convenience.

- Precision grades (ISO Grade 0 – ABEC1) for Single and Double Row Angular Contact Ball Bearings.

- Higher grades (P6 and P5) for Single Row Angular Contact Ball Bearings use combined application.

- Cage options include Pressed Steel, Nylon Fibre, and Brass Cage to suit various operating conditions.

Wrap Up

Angular Contact Ball Bearings are a vital component in industrial machinery, offering exceptional load-bearing capabilities and adaptability. Their unique design, precise contact angles, and versatile classifications make them indispensable in applications requiring the handling of both radial and axial loads. With our comprehensive range of Angular Contact Bearings, you can guarantee the performance and reliability of your machinery across a wide spectrum of industries. Choose KG International for quality, precision, and performance.