Thrust ball bearings are a specialized type of rolling-element bearing designed to handle axial loads while permitting rotation. This guide aims to provide an in-depth understanding of thrust ball bearings, their applications, and key considerations for selecting the right type for your mechanical projects.

Introduction to Thrust Ball Bearings

Definition and Basic Structure

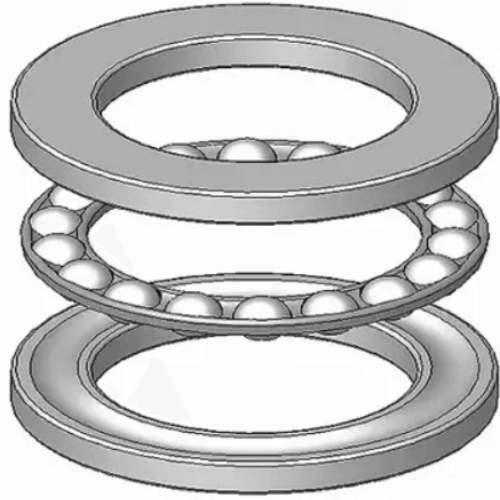

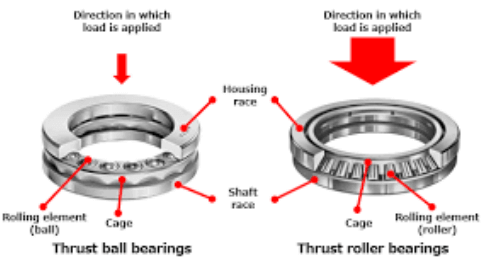

Thrust ball bearings are designed to support axial forces in one or two directions. They consist of a series of balls contained within a ring, known as a raceway. These bearings are distinguished by their ability to handle loads perpendicular to the shaft, unlike radial bearings that handle loads parallel to the shaft.

Components: The primary components of a thrust ball bearing include:

Ball: The rolling element that reduces friction.

Cage: Holds the balls in place and ensures even spacing.

Raceways (Washers): Two flat rings that encase the balls and cage.

Applications of Thrust Ball Bearings

Thrust ball bearings are essential in various industrial and mechanical applications. Their ability to handle axial loads makes them suitable for:

Heavy Machinery: Used in mining and construction equipment.

High Axial Load Applications: Ideal for turbines, pumps, and other machinery where axial loads are predominant.

General Mechanical Projects: Enhances efficiency by reducing friction in numerous mechanical systems.

Selecting the Right Thrust Ball Bearing:

Understanding Load and Speed Requirements

Axial vs. Radial Loads: Thrust bearings are not suitable for heavy radial loads.

Speed Considerations: Bearings must be chosen based on the operational speed of the machinery. High-speed applications require bearings that can maintain performance even under misalignment.

Temperature Factors

Heat Generation: Bearings generate heat during operation, which must be managed effectively.

Environmental Temperature: The lubrication and material should be compatible with the operational temperature range.

Load Capacity

Types of Loads: Thrust bearings must support axial, radial, and combined loads as per the application requirements.

Load Measurement: Accurate measurement of the load types is crucial for selecting a bearing that can handle the expected stress.

Tips for Choosing the Right Thrust Ball Bearing

Assess the Application: Understand the specific requirements of your project, including load type, speed, and temperature conditions.

Precision and Accuracy: High-precision bearings are essential for applications requiring exact load support and minimal friction.

Compatibility with Equipment: Ensure the bearing is compatible with the existing equipment to avoid inefficiencies or potential failures.

Maintenance and Durability: Consider the maintenance needs and durability of the bearing. A well-chosen bearing reduces the need for frequent maintenance and prolongs the machine life.

Cost vs. Quality Trade-off: While cost is a factor, it should not be at the expense of quality and suitability for the intended application.

Installation and Maintenance

Proper installation and regular maintenance are crucial for the optimal performance of thrust ball bearings. Incorrect installation can lead to premature failure, increased maintenance needs, and in severe cases, costly equipment damage. Regular inspections, lubrication, and cleaning are essential to ensure longevity and efficiency.

How Can KG International Be Your Ideal Distributor?

Businesses in Dubai seeking reliable and efficient mechanical components can greatly benefit from range of thrust bearings. KG International, renowned for its dedication to excellence and reliability, provides an extensive array of thrust bearings tailored to meet diverse industrial requirements. Expertly engineered to manage axial loads with high efficiency, these bearings are perfectly suited for a range of uses, encompassing everything from robust, heavy-duty machinery to intricate precision instruments.

One of the key advantages for businesses using thrust bearings is their durability. Constructed with high-quality materials, these bearings can withstand challenging industrial environments, reducing the need for frequent replacements and maintenance. This durability translates into cost savings and increased uptime for businesses, enhancing overall productivity.

Moreover, the thrust bearings are known for their precision engineering. This ensures smooth operation and minimal friction, which is crucial for businesses aiming to optimize the efficiency of their machinery. Reduced friction not only enhances performance but also contributes to the longevity of the equipment.

Additionally, the presence of KG International in Dubai offers local businesses easy access to their products and technical support. This proximity means quicker response times for supply and service, a vital factor for businesses that rely on prompt maintenance and parts replacement to avoid operational downtime.

Also Read : Maximizing Efficiency with Thrust Ball Bearings

Conclusion

Thrust ball bearings play a vital role in various mechanical and industrial applications. Their ability to handle axial loads efficiently makes them indispensable in specific machinery and projects. Selecting the right thrust ball bearing requires a thorough understanding of specific needs such as load types, operational speed, temperature conditions, and maintenance requirements.

By considering these factors, you can ensure enhanced performance, reduced maintenance, and prolonged equipment life, ultimately leading to increased efficiency and cost savings in your mechanical projects.