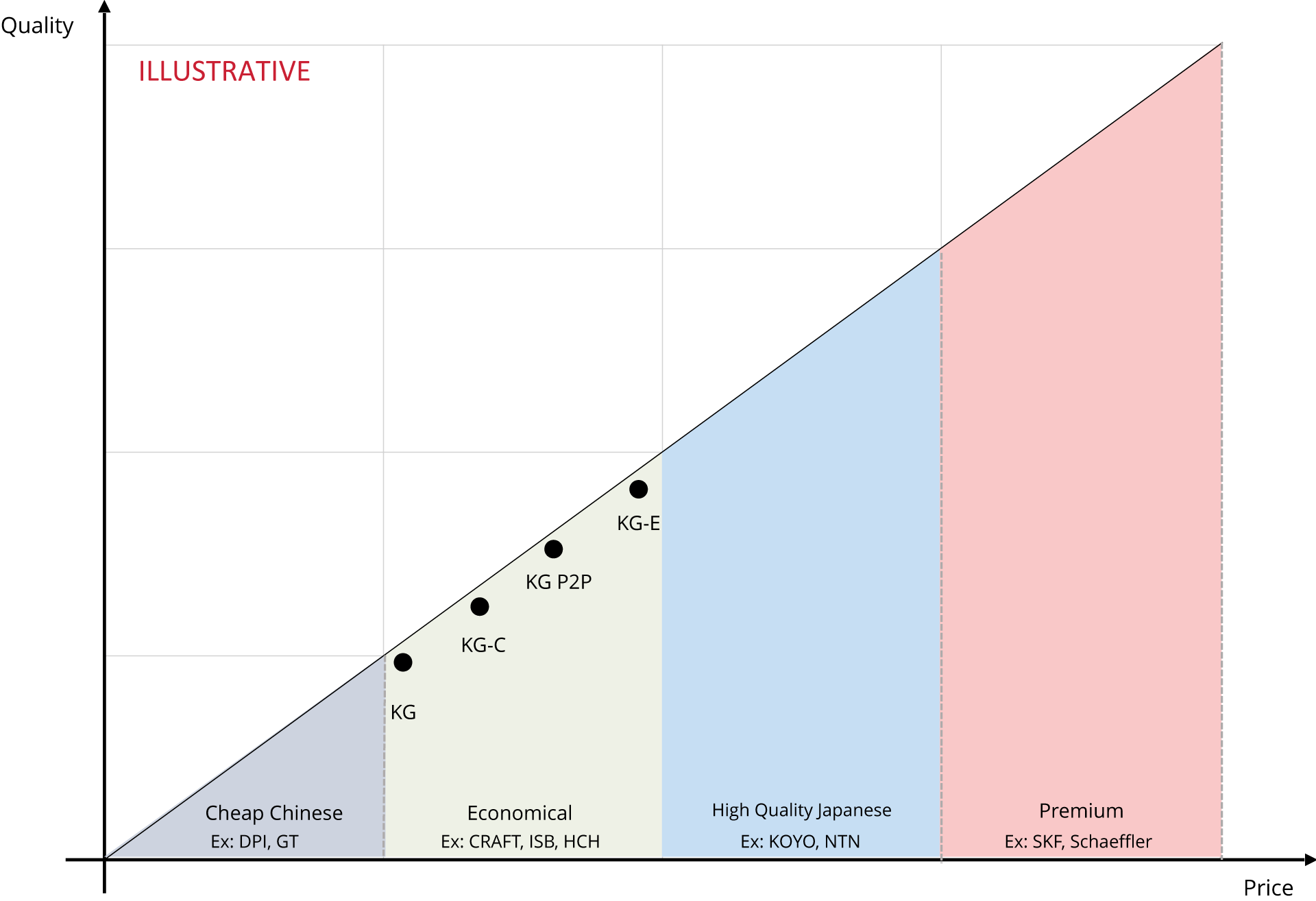

KG brand is over 50years old globally renowned for high quality and reliability and a quality-price balance that makes customers more competitive, productive, and profitable. In particular, KG’s quality control practices are industry-leading and ensure consistent, reliable products at all times. KG’s extensive manufacturing network also ensures business resiliency and a quick ability to manufacturing fit-for-purpose bearings based on customer needs.

KG

Manufacturing Quality

India that are all regularly audited and inspected by dedicated offices in

India and China.

KG bearings have the highest quality in the “economical” bearing segment and leverage ISO:9001 and IATF 16949:2016 certified processes/production facilities to ensure minimal product rejection and applicability in even the most hazardous applications. Our factories are equipped with advanced machineries to ensure manufacturing set up and tolerances as per quality bandwidth.

KG has a solution for all your needs

KG has five brand variants which cater to distinct market segments based on the quality they require

-

KG Blue

-

KG Colorful

-

KG Ultra

-

KG P2P

-

KG-E

KG Blue

Types

- Deep Groove Ball Bearings

- Miniature Ball Bearings

- Angular Contact Ball Bearings

- Cylindrical Roller Bearings

- Tapered Roller Bearings

- Spherical Bearings

- Thrust Roller Bearings

- Pillow Block Bearings

- Adapter Sleeves

- Automotive Bearings

Product Details

Marking: “KG” + Full Bearing no. on the inner ring face for 2RS & ZZ types and on the outer ring face for other types

Seal: Red or Black (occasionally)

Shield: SPCC Yellow

Bearings perfect for the aftermarket due to good quality, and low price

- Precision Class :

- P0, ABEC1

- Raw Material:

- GCr15/SAE 52100

- Roller Grade:

- G10 (Material Grade)

- Tolerance:

- P0 standard

- Grease:

- Hangu 2

- DGBB:

- Z1V1

-

Raceway Track

Roughness:

- 0.12-0.2μm

-

OD Bore

Roughness:

- 0.5-0.6μm

- Roller Grouping:

- 10-15μm (as per Radial Clearance)

KG Colorful

Types

- Deep Groove Ball Bearings

- Angular Contact Ball Bearings

- Cylindrical Roller Bearings

- Tapered Roller Bearings

- Spherical Bearings

- Pillow Block Bearings

- Automotive Bearings

- Miniature Ball Bearings

Product Details

- Precision Class :

- P0, ABEC1

- Raw Material:

- GCr15/SAE 52100

- Roller Grade:

- G10

- Tolerance:

- P0 standard

- Grease:

- Hangu 2

- DGBB:

- Z2V1

-

Raceway Track

Roughness:

- 0.12-0.2μm

-

OD Bore

Roughness:

- 0.5-0.6μm

- Roller Grouping:

- 10-15μm (as per Radial Clearance)

KG Ultra

Types

- Spherical Roller Bearings

- Spherical Roller Thrust Bearings

Product Details

Marking: “KG Ultra” + Full Bearing no. on the outer ring face

Wrapping: Wrapped with a plastic sheet, VCI paper, and waterproof tape to protect from rust and ensure long lasting storage ability

Packaging: Strong, durable, plywood packaging to protect bearings in transport and storage; For bearings lighter than 35kg, we use the KGC packaging

- Precision Class :

- P0, ABEC1

- Speciality :

- Lubrication groove is wider

- Roller :

- Dimple roller to distinguish

- Tolerance :

- Manufacturing tolerance & set up of P0, P6

- Production :

- Controlled in range of P0, P6

- Hardness :

- Throughout uniform hardness

- Load Ratings :

- As per application

- Roller Grouping :

- 5-10μm (as per Radial Clearance)

KG P2P

Types

- Deep Groove Ball Bearings

- Tapered Roller Bearings

- Automotive Bearings

Product Details

Seal: Black

Shield: Silver

- Precision Class :

- P6, ABEC3

- Raw Material :

- GCr15/SAE 52100

- Ball Grade :

- G10

- Tolerance :

- P6 standard

- Grease :

- Kyodo Yushi (Japan), Shell Alvania RL3

- DGBB Quality :

- Z3V2 or higher for smaller bearings; Z2V2 for larger bearings

- Hardness :

-

+/-2 HRC at diff. point

of rings

KG-E

Types

- Radial Ball Bearings

Product Details

Marking: “KG-E” + Full Bearing No. with complete suffixes + Factory, Grease, and Quality Codes on seal/shield for 2RS & ZZ types and on outer ring face for open type

Seal: Black

Shield: Silver

- Precision Class :

- P6, ABEC3

- Raw Material :

- GCr15/SAE 52100

- Ball Grade :

- G10

- Tolerance :

- P6 or higher

- Grease :

- Kyodo Yushi (Japan)

- DGBB Quality :

- Z3V3, Z4V4

- Hardness :

-

+/-2 HRC at diff. point

of rings

KG Blue

KG Blue

Types

- Deep Groove Ball Bearings

- Miniature Ball Bearings

- Angular Contact Ball Bearings

- Cylindrical Roller Bearings

- Tapered Roller Bearings

- Spherical Bearings

- Thrust Roller Bearings

- Pillow Block Bearings

- Adapter Sleeves

- Automotive Bearings

Product Details

Marking: “KG” + Full Bearing no. on the inner ring face for 2RS & ZZ types and on the outer ring face for other types

Seal: Red or Black (occasionally)

Shield: SPCC Yellow

Bearings perfect for the aftermarket due to good quality, and low price

- Precision Class :

- P0, ABEC1

- Raw Material:

- GCr15/SAE 52100

- Roller Grade:

- G10 (Material Grade)

- Tolerance:

- P0 standard

- Grease:

- Hangu 2

- DGBB:

- Z1V1

-

Raceway Track

Roughness:

- 0.12-0.2μm

-

OD Bore

Roughness:

- 0.5-0.6μm

- Roller Grouping:

- 10-15μm (as per Radial Clearance)

KG Colorful

KG Colorful

Types

- Deep Groove Ball Bearings

- Angular Contact Ball Bearings

- Cylindrical Roller Bearings

- Tapered Roller Bearings

- Spherical Bearings

- Pillow Block Bearings

- Automotive Bearings

- Miniature Ball Bearings

Product Details

- Precision Class :

- P0, ABEC1

- Raw Material:

- GCr15/SAE 52100

- Roller Grade:

- G10

- Tolerance:

- P0 standard

- Grease:

- Hangu 2

- DGBB:

- Z2V1

-

Raceway Track

Roughness:

- 0.12-0.2μm

-

OD Bore

Roughness:

- 0.5-0.6μm

- Roller Grouping:

- 10-15μm (as per Radial Clearance)

KG Ultra

KG Ultra

Types

- Spherical Roller Bearings

- Spherical Roller Thrust Bearings

Product Details

Marking: “KG Ultra” + Full Bearing no. on the outer ring face

Wrapping: Wrapped with a plastic sheet, VCI paper, and waterproof tape to protect from rust and ensure long lasting storage ability

Packaging: Strong, durable, plywood packaging to protect bearings in transport and storage; For bearings lighter than 35kg, we use the KGC packaging

- Precision Class :

- P0, ABEC1

- Speciality :

- Lubrication groove is wider

- Roller :

- Dimple roller to distinguish

- Tolerance :

- Manufacturing tolerance & set up of P0, P6

- Production :

- Controlled in range of P0, P6

- Hardness :

- Throughout uniform hardness

- Load Ratings :

- As per application

- Roller Grouping :

- 5-10μm (as per Radial Clearance)

KGTS

KGTS

Made in India bearings with high precision (P6) to improve longevity and durability

Engineered with a guaranteed lifespan of 80,000 KM

Premium-quality solutions catering to a full range of European, American and Asian trucks

Maximum reliability through 100% quality checks, including a test certificate

Enhanced product protection by using high-quality & eco-friendly packaging material

Competitive pricing and strong stock in Dubai

KG Truck Solutions are built to help truck and fleet owners be more competitive, productive, and profitable.

- Precision Class :

- P6, ABEC3

- Raw Material:

- SAE 52100

- Tolerance:

- P6 or higher

- Grease:

- BECHEM (-30° TO 180°)

- Hardness:

- +/-4 HRC at diff, point of rings

KG P2P

KG P2P

Types

- Deep Groove Ball Bearings

- Tapered Roller Bearings

- Automotive Bearings

Product Details

Seal: Black

Shield: Silver

- Precision Class :

- P6, ABEC3

- Raw Material :

- GCr15/SAE 52100

- Ball Grade :

- G10

- Tolerance :

- P6 standard

- Grease :

- Kyodo Yushi (Japan), Shell Alvania RL3

- DGBB Quality :

- Z3V2 or higher for smaller bearings; Z2V2 for larger bearings

- Hardness :

-

+/-2 HRC at diff. point

of rings

Why KG is the preferred choice for moving the world

UNMATCHED QUALITY

FOR CONSISTENCY AND RELIABILITY IN ALL APPLICATIONS

FOR CONSISTENCY AND RELIABILITY IN ALL APPLICATIONS

1

LEADING QUALITY

CONTROL PRACTICES

3

TOP QUALITY

MATERIALS

2

HIGH MANUFACTURING

QUALITY

4

CONSISTENCY AND

RELIABILITY

FOR CONSISTENCY AND RELIABILITY IN ALL APPLICATIONS

1

LEADING QUALITY

CONTROL PRACTICES

2

HIGH MANUFACTURING

QUALITY

3

TOP QUALITY

MATERIALS

4

CONSISTENCY AND

RELIABILITY

WIDE RANGE

TO CATER TO ALL YOUR

CUSTOMERS' NEEDS

TO CATER TO ALL YOUR

CUSTOMERS' NEEDS

5

LARGE AUTOMOTIVE AND

INDUSTRIAL RANGE

7

APPLICATION SPECIFIC

RANGES

6

BRAND VARIANTS TO

SUIT YOUR NEEDS

8

ABILITY TO QUICKLY

DEVELOP OUR RANGE

TO CATER TO ALL YOUR

CUSTOMERS' NEEDS

5

LARGE AUTOMOTIVE AND

INDUSTRIAL RANGE

6

BRAND VARIANTS TO

SUIT YOUR NEEDS

7

APPLICATION SPECIFIC

RANGES

8

ABILITY TO QUICKLY

DEVELOP OUR RANGE

BRAND IDENTITY AND GLOBAL RECOGNITION

ENSURING THAT YOU CAN SCALE AND GROW QUICKLY AND EFFICIENTLY

ENSURING THAT YOU CAN SCALE AND GROW QUICKLY AND EFFICIENTLY

9

STORIED LEGACY AND

STRONG BRAND IMAGE

11

STRONG VALUE

FOR MONEY

10

GLOBAL

PRESENCE

12

BEAUTIFUL AND

HIGH-QUALITY PACKAGING

ENSURING THAT YOU CAN SCALE AND GROW QUICKLY AND EFFICIENTLY

9

STORIED LEGACY ANDSTRONG

BRAND IMAGE

10

GLOBAL PRESENCE

11

STRONG VALUE

FOR MONEY

12

BEAUTIFUL AND HIGH-QUALITY

PACKAGING

UNMATCHED QUALITY

UNMATCHED QUALITY

FOR CONSISTENCY AND RELIABILITY IN ALL APPLICATIONS

FOR CONSISTENCY AND RELIABILITY IN ALL APPLICATIONS

1

LEADING QUALITY

CONTROL PRACTICES

3

TOP QUALITY

MATERIALS

2

HIGH MANUFACTURING

QUALITY

4

CONSISTENCY AND

RELIABILITY

FOR CONSISTENCY AND RELIABILITY IN ALL APPLICATIONS

1

LEADING QUALITY

CONTROL PRACTICES

2

HIGH MANUFACTURING

QUALITY

3

TOP QUALITY

MATERIALS

4

CONSISTENCY AND

RELIABILITY

WIDE RANGE

WIDE RANGE

TO CATER TO ALL YOUR

CUSTOMERS' NEEDS

TO CATER TO ALL YOUR

CUSTOMERS' NEEDS

5

LARGE AUTOMOTIVE AND

INDUSTRIAL RANGE

7

APPLICATION SPECIFIC

RANGES

6

BRAND VARIANTS TO

SUIT YOUR NEEDS

8

ABILITY TO QUICKLY

DEVELOP OUR RANGE

TO CATER TO ALL YOUR

CUSTOMERS' NEEDS

5

LARGE AUTOMOTIVE AND

INDUSTRIAL RANGE

6

BRAND VARIANTS TO

SUIT YOUR NEEDS

7

APPLICATION SPECIFIC

RANGES

8

ABILITY TO QUICKLY

DEVELOP OUR RANGE

BRAND IDENTITY AND

GLOBAL RECOGNITION

BRAND IDENTITY AND GLOBAL RECOGNITION

ENSURING THAT YOU CAN SCALE AND GROW QUICKLY AND EFFICIENTLY

ENSURING THAT YOU CAN SCALE AND GROW QUICKLY AND EFFICIENTLY

9

STORIED LEGACY AND

STRONG BRAND IMAGE

11

STRONG VALUE

FOR MONEY

10

GLOBAL

PRESENCE

12

BEAUTIFUL AND

HIGH-QUALITY PACKAGING

ENSURING THAT YOU CAN SCALE AND GROW QUICKLY AND EFFICIENTLY

9

STORIED LEGACY ANDSTRONG

BRAND IMAGE

10

GLOBAL PRESENCE

11

STRONG VALUE

FOR MONEY

12

BEAUTIFUL AND HIGH-QUALITY

PACKAGING

Resources & catalogs

Product Overview

Full Product Catalog

Mini Product Range Book

KG U Series Leaflet

Why KG? 12 Reasons

Share details below to download!

© KG International FZCO 2022 | All Rights Reserved 2023

Subscribe

Subscribe